Process Overview: Walmart orders glitter from Advantus under the 46WLM DSDC (Direct Store Delivery Consolidation) customer account. The method used to pick and process these orders is unique, so Advantus has a large area in the 12th Street facility that is dedicated to the picking and processing of these orders. The steps below outline the processing of 46WLM orders.

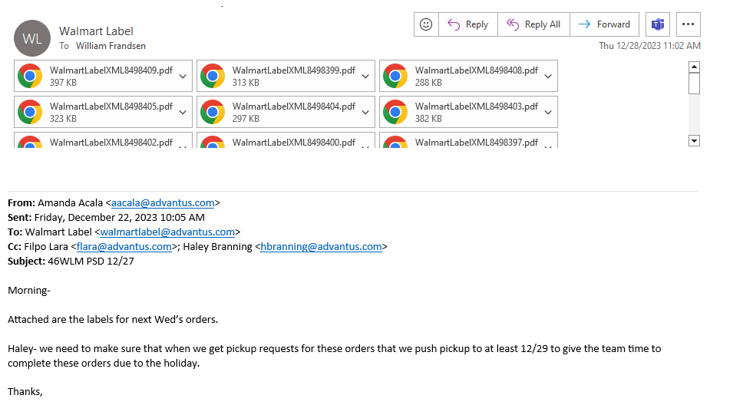

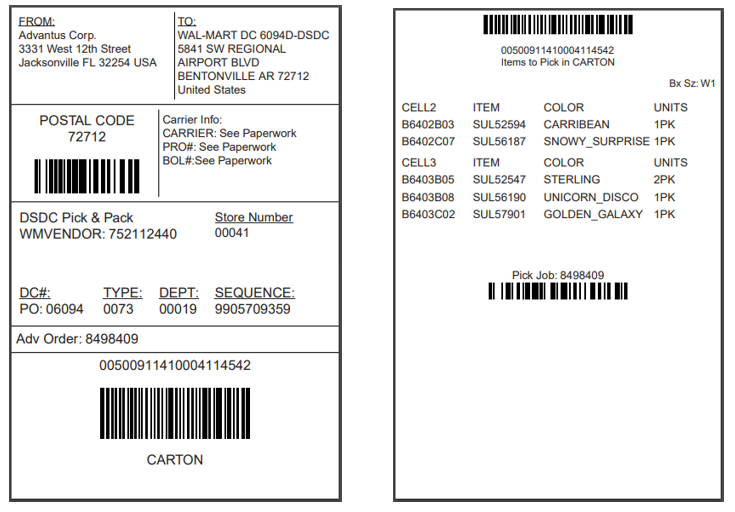

Step 1: Order Management sends an email containing the carton labels needed for each released sales order. Production then prints these labels and takes them to the carton labeling station.

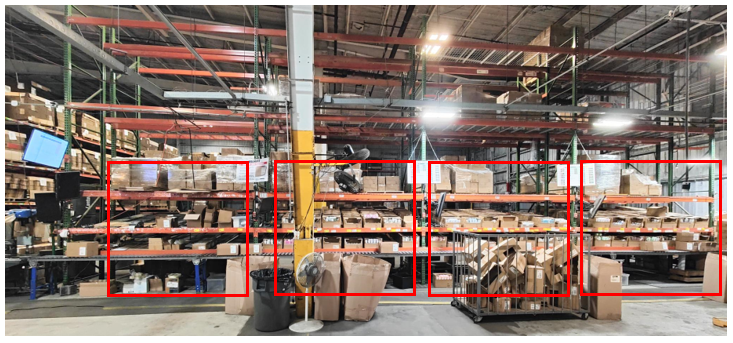

- *Note– For each carton, there will be one label that is applied to the outside of the carton (shipping information) and one that is applied to the inside (items and quantities). The inside label contains the items and quantities needed from each ‘Cell’ within the Walmart picking line. There are 4 cells within the Walmart line, beginning with 1 being the cell furthest to the right, and ending with Cell 4 furthest to the left.

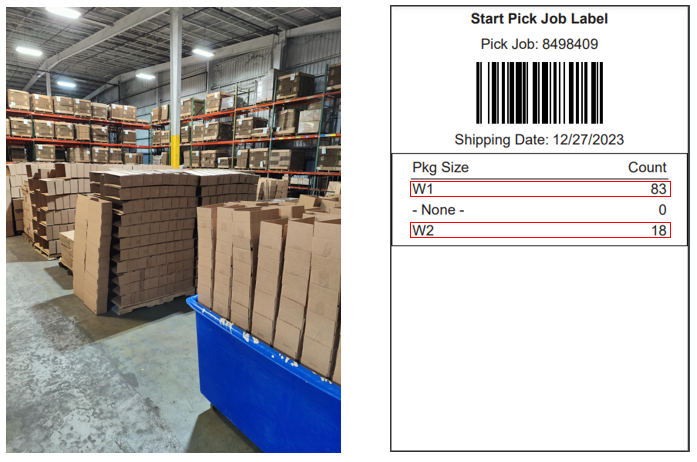

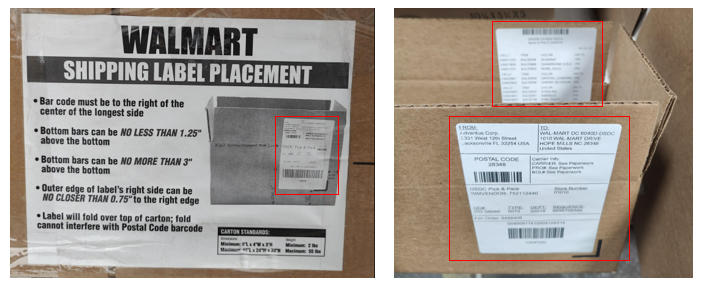

Step 2: Gather the number of cartons needed for each pick job. The first label in every batch (Start Pick Job Label) contains the number of cartons needed for each carton size.

Step 3: Apply the 2 carton labels (inside and outside) to the appropriate cartons according to the shipping label placement guidelines. The ‘Start Pick Job Label’ is applied to the first box within the pick job to signify the beginning of a new order. The ‘Bx Sz’ field in the upper right-hand corner of the ‘items’ label contains the box size coinciding with each set of labels. (See label in Step 1)

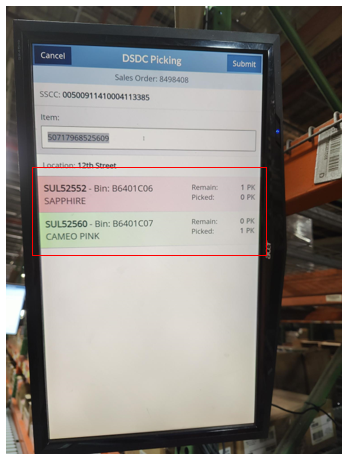

Step 4: Using the scanner in Cell 1, scan the outside label on the first carton. The items and quantities needed within Cell 1 will populate on the Cell 1 screen and will be highlighted in red. These items and quantities will also match what is shown on the label inside of the carton. Locate each item and scan the appropriate quantity needed for each line. Once the line has been fully picked, the line will be highlighted green.

- *Note– Inventory along the Walmart line is regularly replenished, and orders should only be released if NetSuite shows there is enough inventory available to fulfill each item. If we are short inventory, an alert will pop up on the Cell 1 screen after the first carton is scanned. If we do not have enough inventory to replenish the item/quantity needed, this information should be sent to Customer Service so the sales order can be adjusted as necessary.

Step 5: Repeat Step 4, using the scanner unique to cells 2 and 3 as needed until all items have been scanned/picked.

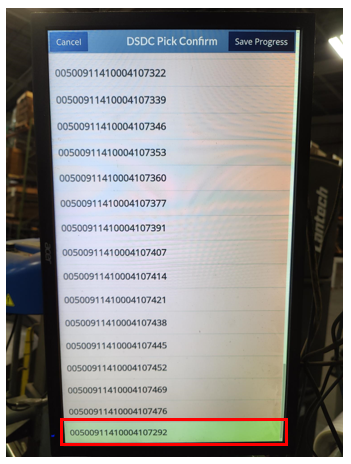

Step 6: Once the carton has been fully picked and has reached Cell 4, scan the carton using the scanner unique to Cell 4. This will complete the picking process for the license plate (carton LP) and once submitted, the license plate will be highlighted in green on the DSDC Pick Confirm screen in Cell 4.

- *Note– Once the final carton has been scanned, the pallet license plate will be printed out. This will need to be applied to the pallet once it has been wrapped.

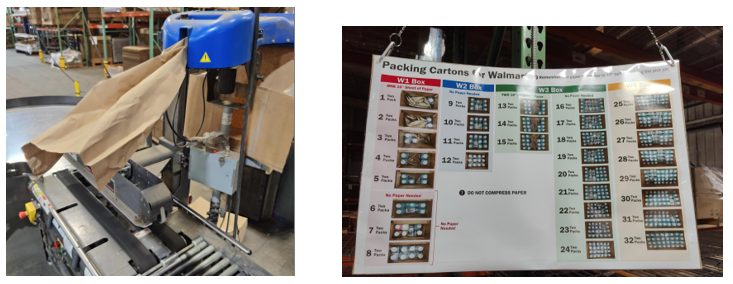

Step 7: Add the appropriate amount of packing paper according to the established guidelines.

Step 8: Once the packing paper has been added, each carton must be taped shut. Center the carton along the two running conveyor belts. The taping machine will tape the top of the carton and will push the finished product onto the rotating sorting table.

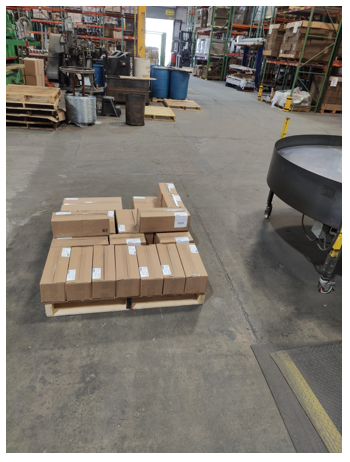

Step 9: As cartons are finished, build the pallet until the pick job has been completed.

Step 10: Once the pallet has been fully built, it will need to be taken to the wrapping machine to be stretch-wrapped and have the pallet LP applied. The pallet will then be moved to the staging area for shipment.

This completes the process of processing 46WLM orders.