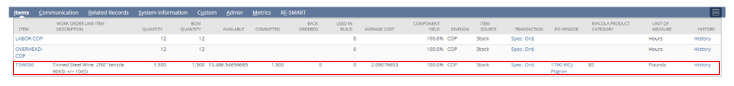

Process Overview: A few of the metal items we manufacture at the 12th Street facility include our deadlock tag fasteners, meat deadlocks, and card holders. All these items have a similar manufacturing process. They are manufactured in bulk and later, are typically re-packed into different package sizes for resale. The process below should be used for manufacturing deadlocks and card holders.

Step 1: Ensure the work order components (wire) have been transferred to the appropriate backflush bin.

Step 2: Move the wire in front of the appropriate machine.

- *Note– The spools of wire are very heavy and should be moved using a forklift or another piece of equipment that is capable of moving reels/spools.

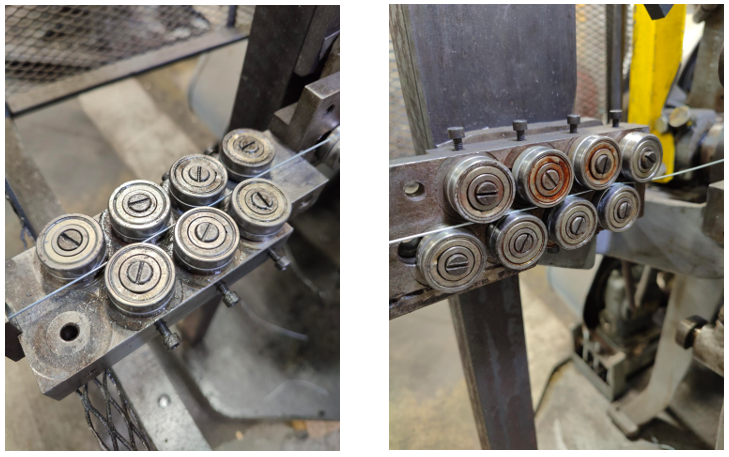

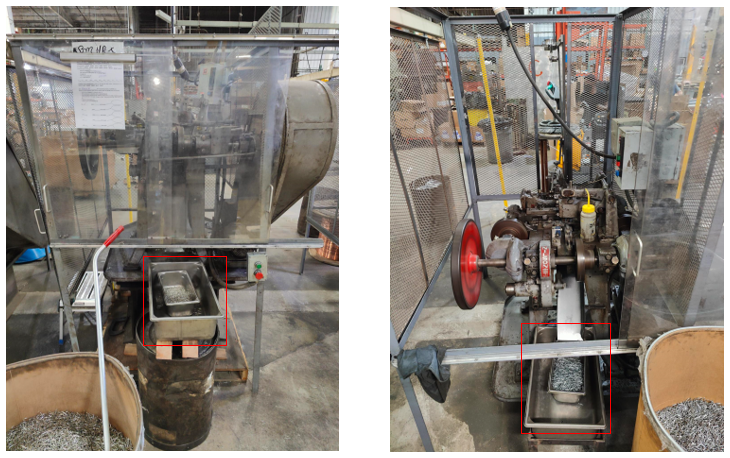

Step 3: Wind the wire through the pulleys and the angular contact bearings until you get to the appropriate stopping point on each machine.

- *Note– The pulleys are used to keep proper tension on the wire while the bearings are used to straighten the wire as it is naturally bent when coming off the spool.

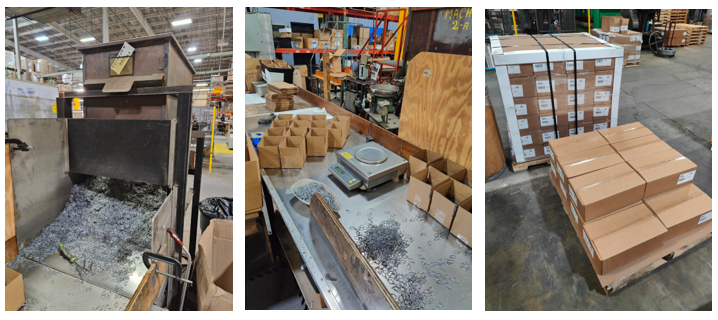

Step 4: Once the wire has been wound through the machine, ensure there is a container in place under the chute to catch the deadlocks/card holders.

- *Note– A small container is initially used to catch the deadlocks/card holders as they need to be regularly inspected before they are added to the bulk barrels.

Step 5: Once the wire has been properly wound through the machine and the container is in place to catch the produced items, turn the machine on and then hit the green Start button to start the machine.

- *Note– Once the machine is running, the red Stop button can be used to stop the machine.

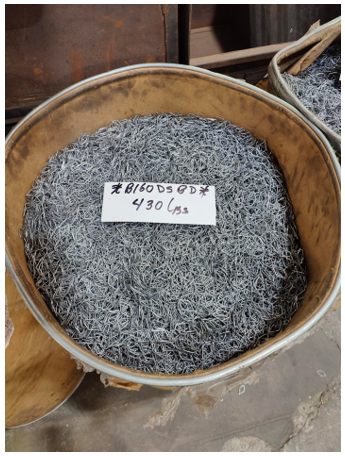

Step 6: Each hour, the produced items are inspected to ensure they meet the manufacturing standards. (Reference the Deadlock Manufacturing Standards process) Once confirmed, the items are emptied into the larger storage barrels next to each machine.

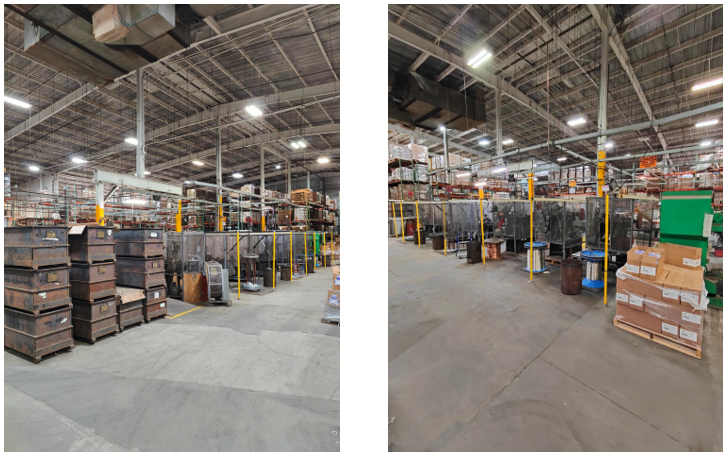

Step 7: After the barrel is filled up, it must be weighed and reported.

Step 8: After the barrel is weighed, the items are then transferred to one of the metal containers for final storage.

This completes the manufacturing process for Advantus’ deadlocks and card holders.

- *Note– As work orders are created, the bulk items will be re-packed into their sellable units of measure. This process includes taking the metal container to the re-packaging area, weighing, and packing the deadlocks/card holders, and then palletizing the finished goods for resale. Pictures below.