Process Overview: Our Seward Trunks are manufactured using roll-formed tongue and groove hardware. This helps keep the top and bottom of the trunk sturdily in place when shut. The tongue and groove is manufactured at our 12th Street facility using a roll-forming machine and is then shipped to our Petersburg facility. The process below should be used when manufacturing tongue and groove.

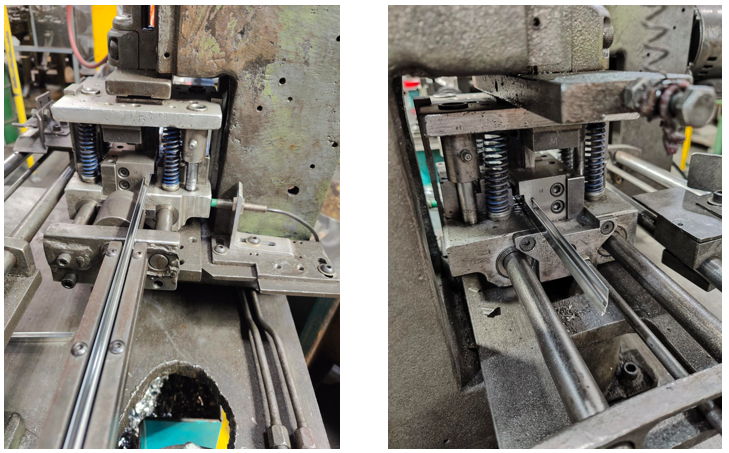

Step 1: Ensure the work order components have been transferred to the appropriate backflush bin.

Step 2: Take the appropriate metal coil and put it on each of the two ‘decoilers’. One wheel is used to produce the tongue while the other wheel is used to produce the groove.

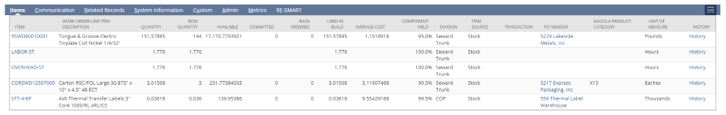

Step 3: Set the finishing plates to the desired length of each tongue and groove piece. This can be done by measuring from the side of the cutter/die housing to the notch on the red tape for each side.

Step 4: Ensure a bin is in place to catch the produced pieces as they are blown off the production line.

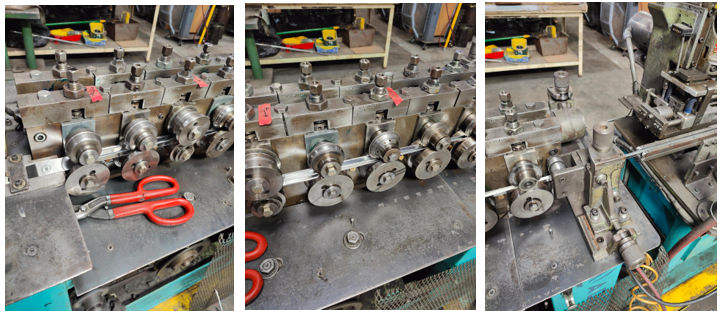

Step 5: On the tongue-forming side, guide the metal through the first slot, along the feed path through the second slot, stopping at the first forming station containing the first set of forming rollers. On the groove-forming side, guide the metal through the first slot, along the feed path, stopping at the first forming station.

Step 6: Once the metal has been fed up to the first set of forming rollers, the machine can be turned on and the roll-formers and cutoffs can be started.

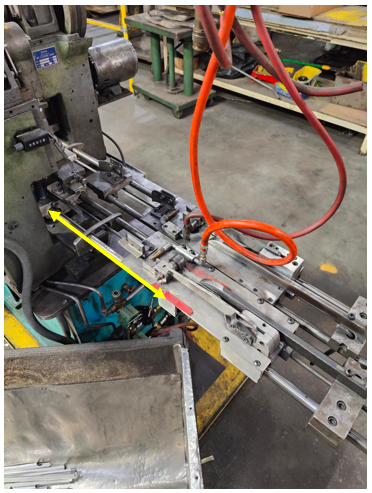

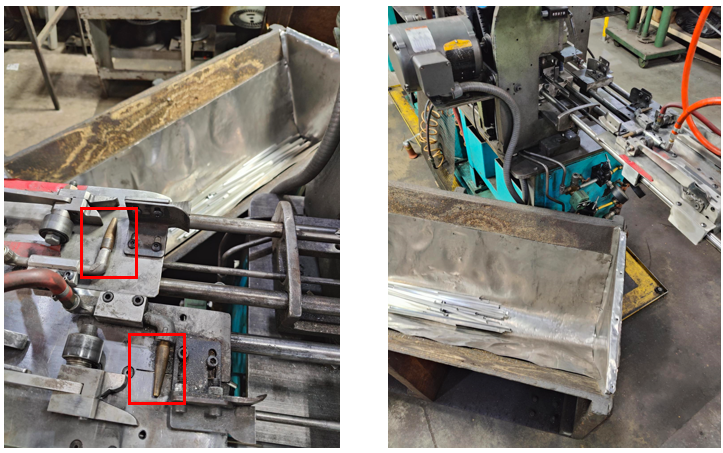

The following shows the process the metal goes through as it is produced.

Step 7: The metal is guided through each of the form-rolling stations. The form-rolling stations are comprised of forming-rollers that drive the metal through the machine while bending the metal to form the desired shape.

Step 8: The finished/formed piece is then guided through the cutter. As each piece hits the length that has been set, it is then cut.

Step 9: As the pieces are cut, compressed air is used to blow the finished pieces off the line and into the bin(s) without stopping production.

Step 10: As the tongue and groove pieces are cut, they are counted and then packed/shipped.

This completes the manufacturing process for the tongue and groove hardware.