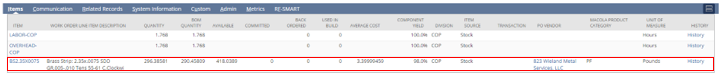

Process Overview: Brass washers and brass fastener heads are manufactured by the same machine, making the process almost identical. The washer is a finished good while the brass fastener head is a component piece for the brass fasteners. The process below should be used when manufacturing brass washers and brass fastener heads.

Step 1: Ensure the work order components (brass) have been transferred to the appropriate backflush bin.

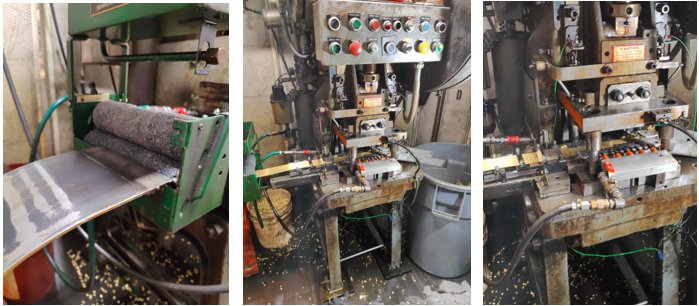

Step 2: Put the roll of brass on the wheel outside of the machine.

Step 3: Feed the brass under the white rotating spool and through the rectangular opening on the side of the machine enclosure.

Step 4: Once inside the enclosure, feed the brass through the grey rollers located in the green housing, and then through the feeding paths as seen below.

Step 5: For the washers, make sure there is a container under the machine to catch the washers as they fall. For the fastener heads, a container needs to be ready under the back of the machine as compressed air shoots the fastener heads towards a chute located in the back of the machine. Also, there should always be a receptacle on the right-hand side to catch the scrap brass coming out of the chute.

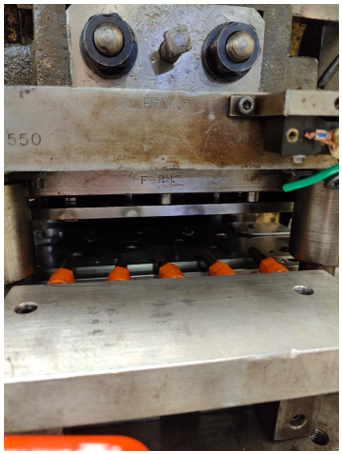

Step 6: Ensure the appropriate die is in place, depending on the item being produced.

Step 7: Once the machine has been set up for the appropriate item and the brass and receptacles are in place, the machine is ready to turn on and start.

Step 8: Once the machine is turned on, the brass is guided through to the die where it is punched, the items are produced and the scrap is disposed of.

Step 9: After the washers/fastener heads have been produced, they are then de-greased and weighed before being packaged for storage/-re-sale. This completes the manufacturing process of brass washers and fastener heads.