Process Overview: As our meat deadlocks and deadlock tag fasteners are produced, some standards must be met before they are put into inventory. If the standards are not met, the deadlocks and tag fasteners are not able to be re-sold. The process below should be used to ensure these items meet the manufacturing standards.

Frequency: To ensure the deadlocks are consistently meeting the required standards, they must be checked every hour.

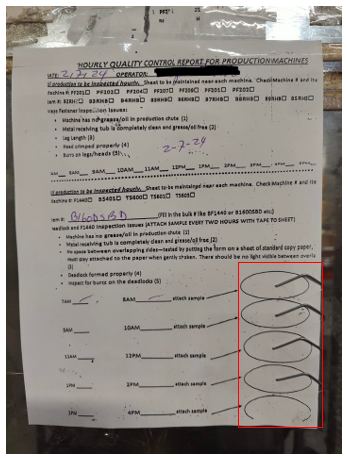

Step 1: Ensure there is an ‘Hourly Quality Control Report for Production Machines’ report on the machine where the deadlocks are being produced. This report contains 5 checks that must be completed and can be found here: SharePoint > Advantus Corp > Advantus Operations – Documents > SharePoint > Forms > Hourly QC Report for Production Machines The following fields should be filled out before running the machine:

- Date: Date the deadlocks are being produced.

- Operator: Employee checking on and overseeing the production of the deadlocks.

- Item #: Item number being produced.

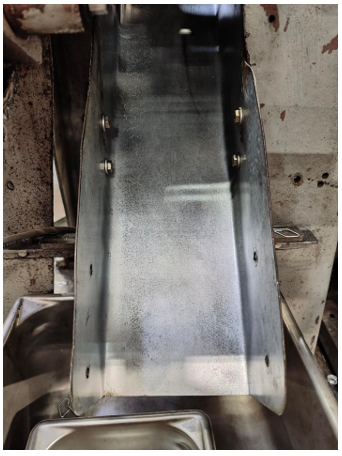

Step 2: (Check #1) Make sure there is no grease/oil in the production chute.

Step 3: (Check #2) Make sure the metal receiving container is completely clean and grease/oil-free.

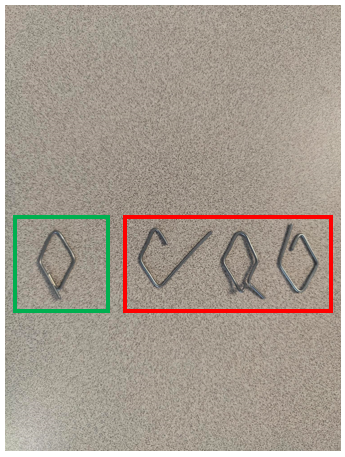

Step 4: (Check #3) Take a few of the deadlocks out of the container catching everything coming out of the chute. Make sure there is no space between overlapping sides- This is tested by putting the deadlock on a sheet of standard copy paper and when the paper is gently shaken, the deadlock must stay attached. There should be no visible light between overlaps. Every 2 hours, a deadlock that was tested must be attached to the report in the spot(s) shown.

Step 5: (Check #4) Ensure the deadlock is formed properly.

Step 6: (Check #5) Inspect for burrs on the deadlocks.

After all checks have been completed, the deadlocks can be transferred to the bulk barrels. This completes the process used to ensure our deadlocks meet manufacturing standards.