Sulyn TRA/LHAMA and Letter of Guarantee Process for New Items

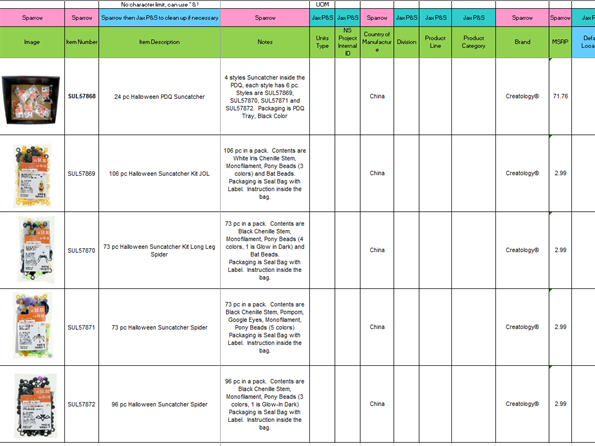

A New Item Form (NIF) will be sent out from Sparrow (currently by Melissa). This form will be sent to Product and Sourcing (currently Rachel Caesar) as well as Product Compliance. This form details the new items that we are creating for a specific customer (Michael’s, Joann’s, Hobby Lobby, etc.). The material composition can be found in this spreadsheet. P&S will enter the items in NetSuite. For PC this is just informational and a heads up.

- For new Michaels items the following things will be happening. PC cannot create the TRF in MiPCS (their testing request system) until these are completed.

- Michaels enters the product information in their system & then

- P&S connects the product to the factory in the Michaels system

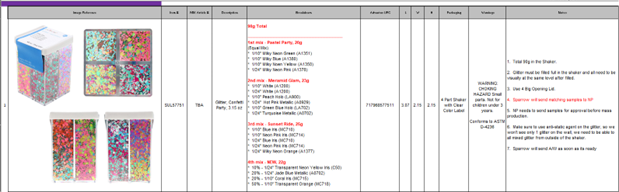

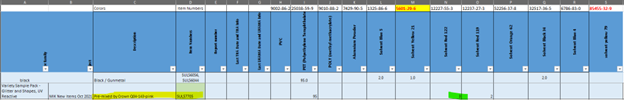

Next the Factory Info Sheet will be sent out by Sparrow (currently Yolanda). This is a spreadsheet that is sent to the factories. It contains the breakdown of mixes, kits and packages. This additional information is needed for the TRF, possible grouping and TRA/LHAMA.

Once the Factory Info Sheet has been received and POs have been cut it’s time to move forward with the TRA/LHAMA process.

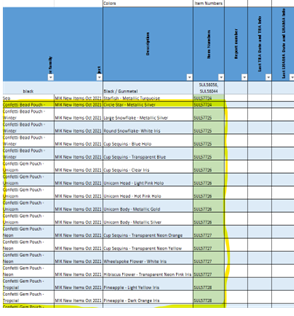

Each element of a new item that needs a TRA/LHAMA needs to be added to the specific factory and item Master CAS spreadsheet located on the S Drive (glues, glitter/sequins and sparkle sand have different spreadsheets). Use the breakdown column of the Info Sheet to see exactly what makes ups each item and what needs to be entered in the Master CAS spreadsheet.

Current Spreadsheet Locations

Ningbo Praise: S:\Compliance\Product Testing & Compliance\TRA & LHAMA, USP, GC Scans\Sulyn\Ningbo Praise

Total Design: S:\Compliance\Product Testing & Compliance\TRA & LHAMA, USP, GC Scans\Sulyn\Total Design

Once all elements/items are entered into the Master CAS spreadsheet it needs to be sent to the factory for the CAS information. It will take them a few days to get the information back.

Once the completed Master CAS spreadsheet is received this information will determine if a new TRA/LHAMA is needed or if the items can be tired back to a previous test.

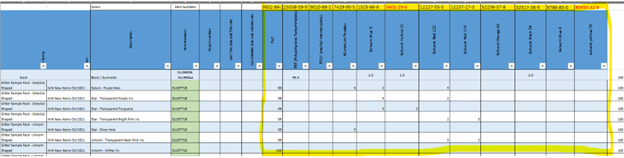

First look at items being sent for actual testing, not grouped items. Items sent for testing have to have a TRA/LHAMA completed before testing or a Letter of Guarantee. Items grouped can have a TRA/LHAMA completed after testing if necessary.

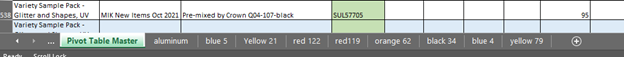

Review the color chemical component for that specific element/item and find the one with the highest value. The example below is “Pre-mixed by Crown Q04-143-pink SUL57705” and the highest color chemical component is Solvent Red 122.

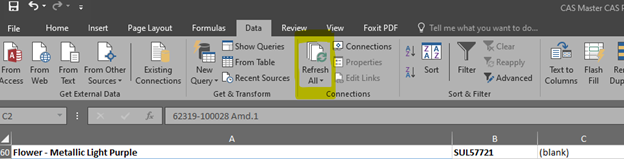

Navigate to the coordinating tab at the bottom of the spreadsheet.

Press the “Refresh All” data button on the top toolbar.

No New TRA/LHAMA Needed:

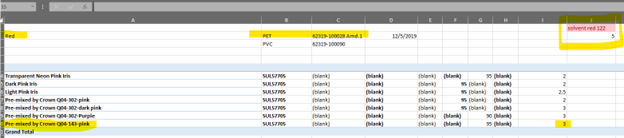

The highest limit tested for that specific color chemical component will be found at the top right hand corner of each specific tab. As long as the element/item in question is below that number, and not highlighted in red, it can be tied back to the TRA/LHAMA listed at the top of that color chemical component tab. The example below shows Solvent Red 122 was tested with a level of 5 and our item is 3 so it does not need a new TRA/LHAMA. This item can be tied back to the TRA/LHAMA for PET 62319-100028 Amd.1 under the color Red from 12/5/2019. This information is also on the top of the specific color chemical component tab.

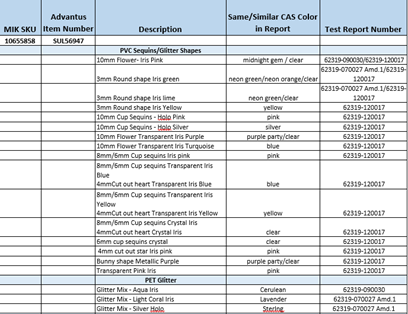

If an item does not need a new TRA/LHAMA a Letter of Guarantee (LOG) would be created. The element/item description, similar color from previous TRA/LHAMA and TRA/LHAMA report number need to be copied over to a new table.

Previous LOG tables

Ningbo Praise: S:\Compliance\Product Testing & Compliance\TRA & LHAMA, USP, GC Scans\Sulyn\Ningbo Praise\LOG – information to build LOG

Total Design: S:\Compliance\Product Testing & Compliance\TRA & LHAMA, USP, GC Scans\Sulyn\Total Design\LOG spreadsheets – to make the LOG

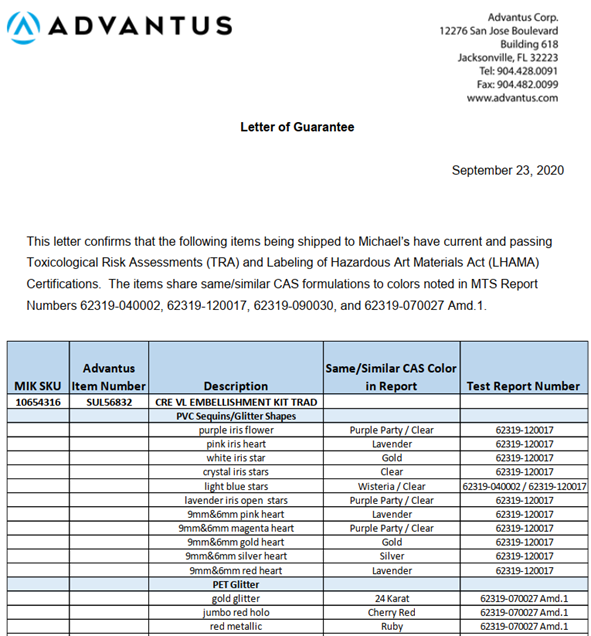

Once this information for the LOG is compiled in the table for all items it needs to be added to the Advantus letterhead. Below is an example of a completed LOG (minus the signature from the product compliance specialist).

New TRA and LHAMA Needed:

If the highest color chemical component for an element/item is above the highest limit that was tested, or the highest color chemical component has never been tested, it will need a TRA and LHAMA completed by the lab.

Ingredient lists need to be created for any element/item needing evaluation. Up to 10 elements/items can be sent for one report. Ingredient lists are created by product compliance using the information from the Master CAS Spreadsheets. Each lab has their own form you have to put this information on to complete the ingredient lists. MTS and BV also require photos of the whole product.