Process Overview: The below process and associated guidelines should be used when palletizing inventory being unloaded off an inbound shipment.

Step 1: Ensure there are enough pallets in your area and that each pallet has a pallet cover.

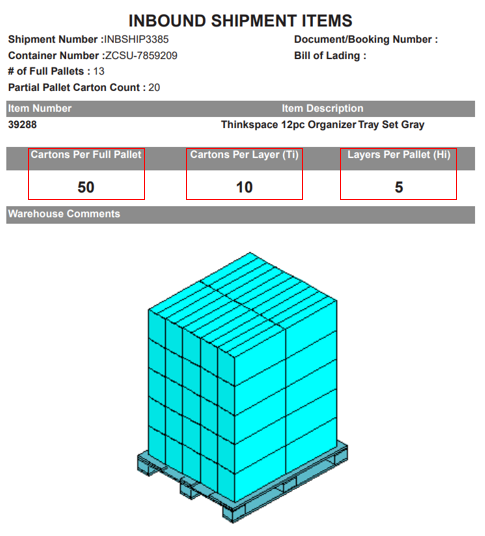

Step 2: Ensure that you have both 1) Received the Ti/Hi Pallet Build for the pallet being built and 2) The instructions are clear and make sense. If there are any questions or concerns, please address them before building the pallet.

- Ti = Cartons Per Layer– Number of cartons on each horizontal layer of the pallet.

- Hi = Layers Per Pallet– Number of vertical layers of cartons per pallet.

- Cartons Per Full Pallet– Number of cartons that will be on each fully built pallet.

- *Note– The carton seam should be face-up on the Ti/Hi Pallet Builds except for when building pallets of flip shelves.

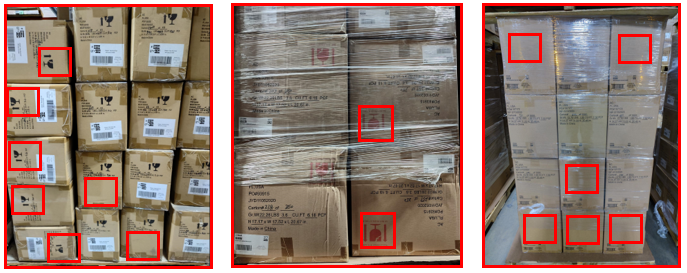

Step 3: As items are taken off the conveyor and built according to the Ti/Hi specifications, make sure the item label and/or item information and barcode are facing outward, and the carton is oriented properly with the arrows (where applicable) are facing upward along with the label. For cartons that do not have the arrows printed on them, ideally, they are facing upward as well but minimally, the cartons should be oriented so that the labels/writing/pictures are all facing the same way on the pallet. For builds that require some cartons to be oriented sideways, the labels/writing/pictures on all these cartons should face the same direction.

Properly Built Pallets

- In the above examples, all cartons that have Upward Arrows are facing upward and cartons without upward arrows are oriented the same way, providing consistency.

Improperly Built Pallets

- In the above examples, there are cartons with Upward Arrows that are flipped upside down and cartons without Upward Arrows that are not oriented the same way to provide consistency.

Step 4: Once the pallet has been built according to the Ti/Hi specifications, we will then need to wrap the pallet. Wrap the pallet according to the Advantus Inbound Pallet Wrapping Process.

This completes the pallet building process for received inventory.