Process Overview: To ensure received inventory counts are 100% correct, it is essential that we accurately receive all items on an inbound shipment. The below process should be used to confirm that palletized inventory has been built properly and to confirm the quantity of each item received on the inbound shipment.

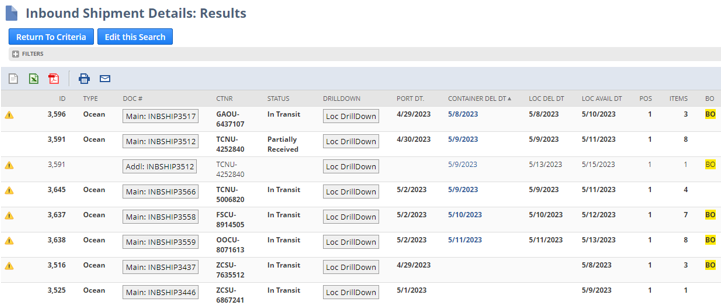

Step 1: Navigate to the Inbound Shipment Details screen. (Path: Shipping & Receiving tab > Inbound Shipments > Inbound Shipment Details)

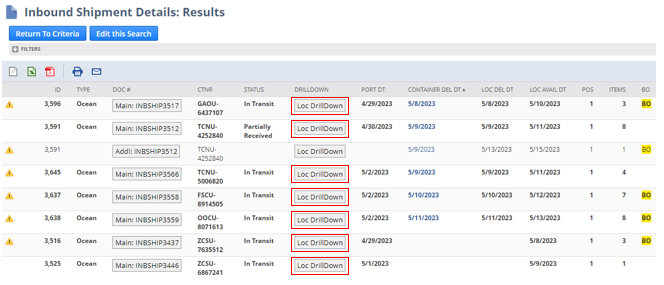

Step 2: Click the Loc DrillDown button to view the items and number of cartons being received. If items are going to additional locations on the inbound shipment, click the Loc Drilldown button that is associated with the ‘Main’ Doc #.

- *Note– If more than one item is being received, proceed to Step 4.

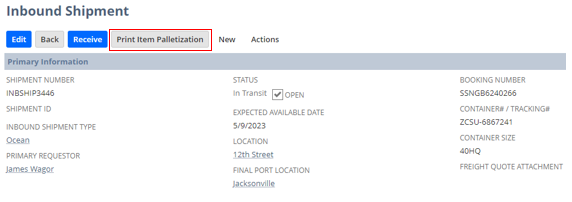

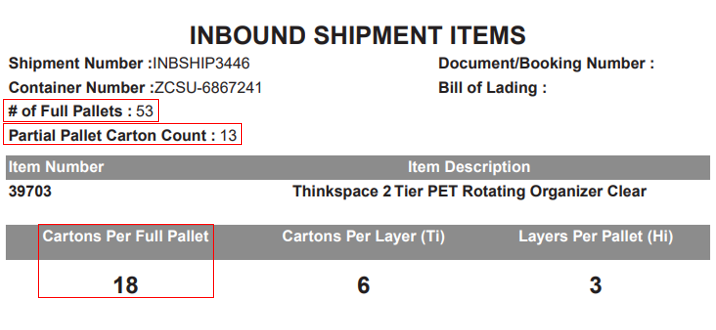

- *Note– If only one item is being received, you will be taken to the Inbound Shipment page for the inbound shipment being received. From here, click the Print Item Palletization button and print the Inbound Shipment Items palletization build to check against the received inventory. (This may have already been printed out during the Inbound Shipment Receiving process)

Step 3: Use the Inbound Shipment Items palletization page to confirm item quantities. This page contains the number of full pallets, the number of cartons per pallet, and the number of cartons on the partial pallet; if applicable.

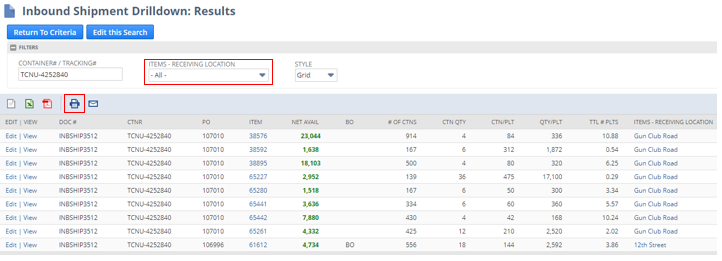

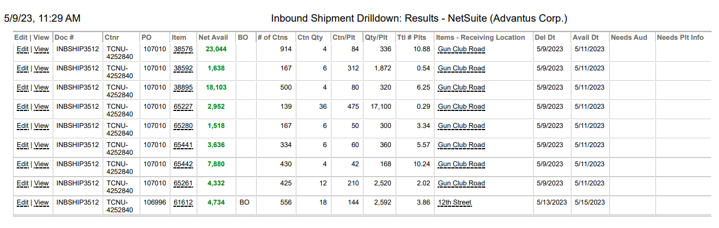

Step 4: If more than one item is being received, you will be taken to the Inbound Shipment Drilldown: Results page. Click the Print icon to print this page.

- *Note– If there are items across multiple locations on the inbound shipment, update the Items – Receiving Location filter to ‘-All-‘ to show all items. Items for separate locations will be received and then sent to the separate location via a Transfer Order.

Step 5: Use the Inbound Shipment Drilldown: Results page to count and confirm the palletized, received items before receiving the inbound shipment into NetSuite.

This completes the process for confirming inbound shipment quantities.