Process Overview– Once an inbound pallet has been built to the necessary specifications, this process and associated guidelines should then be used when wrapping the fully built pallet.

Step 1: Put enough of the end of the stretch wrap between the two corner cartons on the bottom layers so that it stays in place while completing the first layer of wrap around the pallet.

- *Note– As the first go-around is being completed, ensure that the stretch wrap completely covers the starting point where the wrap is inserted between the cartons.

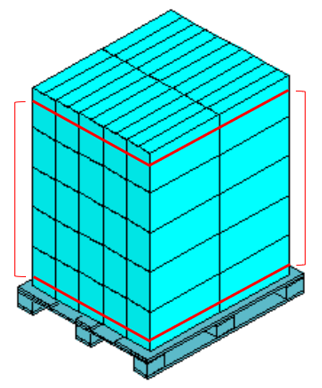

Step 2: Wrap the pallet so that at least half of the bottom and half of the top layers are covered. (Between the red lines below) This should equal roughly 3-4 total wraps around the pallet.

- *Note– While wrapping, make sure to keep a consistent firm stretch on the film to ensure the cartons are as secure as possible. Each layer should overlap the previous layer while moving up or down the pallet.

Step 3: Once we have completed the final level of wrapping, rip the stretch wrap and push it against the top layer so that it lays as flat as possible.

This completes the inbound pallet wrapping process.