Due to the manual assembly of the Seward Trunk skus, mistakes happen and leave the trunks in imperfect condition. These issues are typically cosmetic in nature and do not affect the product performance. Instead of trashing the trunks, we try to liquidate them as “seconds” or “scratch and dent” inventory.

There are two scenarios in which scratch and dents (S&D) occur.

- A trunk is identified as a scratch and dent directly off the production line:

- Production is reported against the first quality trunk item number

- Supply Chain Scheduler, or appropriate party, is alerted to the S&D issue and given to the following information:

- Item number of first quality trunk

- Quantity of “S&D” trunks

- Supply Chain Scheduler, or appropriate party will then create a work order for the “S&D” trunk

- The trunk is immediately labeled with the S&D sticker

- Apply label inside the trunk, behind the lock. Carefully place the label, since the adhesive will cause damage to the paper trunk liners and the exposed wood on trucks without liners

- Once placed, verify the label is well-adhered to the trunk, especially around all edges.

- Note that the adhesive takes about 48 hours to completely cure once placed on a trunk

- Package trunk into carton and label with the S&D barcode label corresponding to the product

- Additional packaging is not used for S&D trunks

- Record production against open work order for S&D trunk

- Transfer trunk from PDock to appropriate bin location

- If the trunk is identified as scratch and dent in some other way and has already been received into a PBG bin:

- Supply Chain Scheduler, or appropriate party, is alerted to the S&D issue and given the following information:

- Item number of first quality trunk

- Quantity of S&D Trunks

- Supply Chain Scheduler, or appropriate party, will then create work order for the S&D trunk

- The Trunk is then labeled with the S&D sticker

- Apply label inside the trunk, behind the lock. Carefully place the label, since the adhesive will cause damage to the paper trunk liners and the exposed wood on trunks without liners

- Once placed, verify the label is well-adhered to the trunk, especially around all edges of the label.

- Note that the adhesive takes about 48 hours to completely cure once placed on a trunk

- Repack trunk in a carton and relabel with the S&D barcode corresponding to the product.

- Report against open Work Order for S&D Trunk

- Transfer to the correct bin location

- Supply Chain Scheduler, or appropriate party, is alerted to the S&D issue and given the following information:

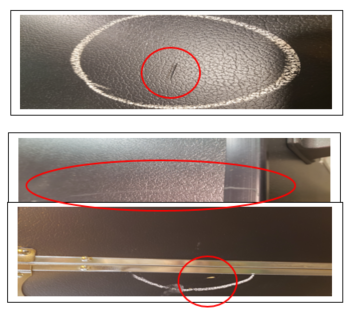

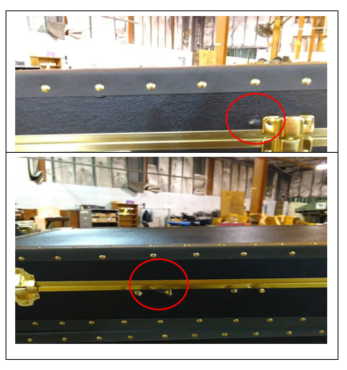

Scratch & Dent items are those with cosmetic blemishes which do not affect the functionality of the product. The below are examples of what is acceptable to be classified and resold as a S&D.

Acceptable to be classified as S&D:

Nick’s

Tears

Discoloration

Tongue & Groove Dents

Dents in Hardware

Not Acceptable to classify as S&D

Holes

Gashes

Extreme Physical Damage

When deemed unacceptable as a First, or a S&D, product will be throw away. A record, Form PBG-003, of this will be kept to report back to Supply Chain Scheduler, or appropriate party, to ensure inventory is accurately accounted for within the scrap factor, or if additional alternations need to be made.

Material Scraping

Item #: _______________________________________

QTY: ________________________________________

Description: ________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

Operator Initials: _________________________ Date: ___________________________

Authorized by: _________________________ Date: ____________________________

PBG-003